DTC P1589:00

Intake shutter valve circuit range/performance problem

DETECTION CONDITION

• The actual intake shutter valve opening angle is 4.2 ° larger than the target opening angle for a continuous 5 s when the following conditions are met.

-

― The following conditions continue for 2 s:

-

• Battery voltage: 8 V or more• Target intake shutter valve opening angle: below 75 °• Target intake shutter valve opening angle is in the closed direction.• Change in speed of the target intake shutter valve: Less than 0.25 °/msec.

― Intake shutter valve control: Being performed -

• The actual intake shutter valve opening angle is 4.2 °smaller than the target opening angle for a continuous 5 s when the following conditions are met.

-

― The following conditions continue for 2 s:

-

• Battery voltage: 8 V or more• Target intake shutter valve opening angle: below 75 °• Target intake shutter valve opening angle is in the open direction.• Change in speed of the target intake shutter valve: Less than 0.25 °/msec.

― Intake shutter valve control: Being performed -

Diagnostic support note

• This is a continuous monitor (CCM).

• The check engine light illuminates if the PCM detects the above malfunction condition during the first drive cycle.

• FREEZE FRAME DATA/Snapshot data is available.

• DTC is stored in the PCM memory.

FAIL-SAFE FUNCTION

• PCM restricts engine torque.

• Inhibits the auto DPF regeneration control.

• Fully open the intake shutter valve.

• Inhibits the compulsory DPF regeneration control.

• Inhibits the EGR control.

• PCM restricts engine-transaxle integration control. (ATX)

• Inhibits engine-stop by operating the i-stop function.

POSSIBLE CAUSE

• Intake shutter valve connector or terminals malfunction

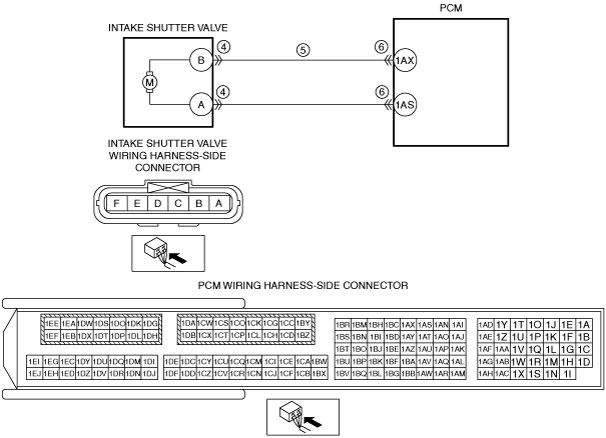

• Short to ground in wiring harness between intake shutter valve terminal B and PCM terminal 1AX

• PCM connector or terminals malfunction

• PCM malfunction