|

STARTER INSPECTION [SKYACTIV-G 1.5, SKYACTIV-G 2.0, SKYACTIV-G 2.5]

id0119i5800300

On-vehicle Inspection

1. Verify that the battery is fully charged. (See BATTERY INSPECTION [SKYACTIV-G 1.5, SKYACTIV-G 2.0, SKYACTIV-G 2.5].)

2. The starter is normal if it rotates smoothly and without any noise when the engine is cranked.

No-load Test

1. Verify that the battery is fully charged. (See BATTERY INSPECTION [SKYACTIV-G 1.5, SKYACTIV-G 2.0, SKYACTIV-G 2.5].)

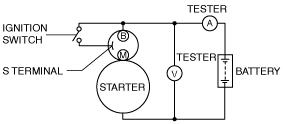

2. Connect the starter, battery, and a tester as shown in the figure.

am6xuw00002343

|

3. Operate the starter and verify that it rotates smoothly.

4. Measure the voltage and current while the starter is operating.

Magnetic Switch Operation Inspection (Without i-stop)

Pull-out test

1. Verify that the starter motor pinion is extended while battery positive voltage is connected to terminal S and the starter body is grounded.

am6xuw00002344

|

Return test

1. Disconnect the motor wire from terminal M.

2. Connect battery positive voltage to terminal M and ground the starter body.

am6xuw00002345

|

3. Pull out the drive pinion with a screwdriver. Verify that it returns to its original position when released.

Pinion Gap Inspection (Without i-stop)

1. Pull out the drive pinion with the battery positive voltage connected to terminal S and the starter body grounded.

am6xuw00002344

|

2. Measure the pinion gap while the drive pinion is extended.

am6zzw00002377

|

Starter Inner Parts Inspection (Without i-stop)

Armature

1. Verify that there is no continuity between the commutator and the core at each segment using a ohmmeter.

am6zzw00002378

|

2. Verify that there is no continuity between the commutator and the shaft using a ohmmeter.

am6zzw00002379

|

3. Place the armature on V-blocks, and measure the runout using a dial indicator.

am6zzw00002380

|

4. Measure the commutator diameter.

am6zzw00002381

|

5. Measure the segment groove depth of the commutator.

am6zzw00002382

|

Magnetic switch

1. Inspect for continuity between terminals S and M using a ohmmeter.

am6xuw00002346

|

2. Inspect for continuity between terminal S and the body using a ohmmeter.

am6xuw00002347

|

3. Verify that there is no continuity between terminals M and B using a ohmmeter.

am6xuw00002348

|

Brush and brush holder

1. Verify that there is no continuity between each insulated brush and plate using a ohmmeter.

am6zzw00002386

|

2. Measure the brush length.

ac5uuw00002441

|

3. Measure the brush spring force using a spring balance.

am6zzw00002388

|