|

DTC P2002:00 [SKYACTIV-D 2.2]

id0102s4150200

Details On DTCs

|

DESCRIPTION |

Diesel particulate filter function decreased |

|

|---|---|---|

|

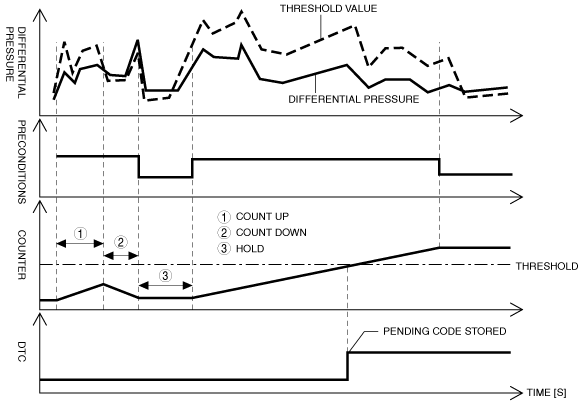

DETECTION CONDITION

|

Determination conditions

|

• The difference in the pressure before and after passing the diesel particulate filter of less than the specified value is detected for 2s.

|

|

Preconditions

|

• All of the following conditions are met for 0.16 s:

|

|

|

Drive cycle

|

• 2

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• Exhaust gas pressure sensor No.2

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Check engine light is illuminated

|

|

|

POSSIBLE CAUSE

|

• Erratic signal to PCM

• Exhaust gas leakage from exhaust system

• Pipe between exhaust gas pressure sensor No.2 and catalytic converter restriction and/or damaged or improper routing

• Exhaust gas pressure sensor No.2 malfunction

• Catalytic converter or diesel particulate filter malfunction (deformation, damage)

• PCM malfunction

|

|

System Wiring Diagram

Function Explanation (DTC Detection Outline)

am6zzw00014372

|

VERIFY TROUBLESHOOTING COMPLETED

1. Connect the M-MDS to the DLC-2.

2. Display the PM_GEN using the M-MDS data logger function.

3. Drive the vehicle until the value of the PM_GEN exceeds 0.37 g/l {0.023 lb/ft3}.

4. Display the EXP_DIF_AVE and EXH_FL using the M-MDS data logger function.

5. Drive at a constant speed for 4 s under the following conditions.

6. Verify that the values of the PIDs EXP_DIF_AVE and EXH_FL are the standard or more.

Standard

atrizt00000057

|

PID Item/Simulation Item Used In Diagnosis

PID/DATA monitor item table

|

Item |

Definition |

Unit |

Condition/Specification |

|---|---|---|---|

|

EXH_FL

|

Exhaust gas amount

|

m3/min

|

• Displays exhaust gas amount

|

|

EXHP_DIF_AVE

|

Average value of the pressure difference before and after passing through the diesel particulate filter

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

• Display average value of the pressure difference before and after passing through the diesel particulate filter

|

|

PM_GEN

|

PM generation amount

|

—(g/l, lb/ft3)

|

• Displays the PM generation amount

|

Function Inspection Using M-MDS

|

STEP |

INSPECTION |

ACTION |

|

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: IDENTIFY TRIGGER DTC FOR FREEZE FRAME DATA

• Is the DTC P2002:00 on FREEZE FRAME DATA?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the troubleshooting procedure for DTC on FREEZE FRAME DATA.

(See DTC TABLE [SKYACTIV-D 2.2].)

|

||

|

3

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the FREEZE FRAME DATA/snapshot data on the repair order.

|

—

|

Go to the next step.

|

|

4

|

PURPOSE: VERIFY RELATED PENDING CODE AND/OR DTC

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Are any other PENDING CODEs and/or DTCs present?

|

Yes

|

Go to the applicable PENDING CODE or DTC inspection.

(See DTC TABLE [SKYACTIV-D 2.2].)

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

||

Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: INSPECT EXHAUST SYSTEM FOR MALFUNCTION

• Inspect the exhaust system for a malfunction.

• Is there a malfunction in the exhaust system?

|

Yes

|

Repair or replace the malfunctioning location, then go to Step 4.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: INSPECT EXHAUST GAS PRESSURE SENSOR-RELATED PIPE FOR MALFUNCTION

• Inspect the exhaust gas pressure sensor-related pipe for a malfunction.

• Is there a malfunction in the exhaust gas pressure sensor-related pipe?

|

Yes

|

Repair or replace the malfunctioning location, then go to Step 4.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: INSPECT EXHAUST GAS PRESSURE SENSOR

• Inspect the exhaust gas pressure sensor.

• Is the exhaust gas pressure sensor normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the exhaust gas pressure sensor, then go to the next step.

|

||

|

4

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Reconnect all disconnected connectors and hoses.

• Clear the DTC from the PCM memory using the M-MDS.

• Verify that repairs have been completed.

• Are the PIDs EXP_DIF_AVE, EXH_FL, and PM_GEN the standard or more?

|

Yes

|

Go to the next step.

|

|

No

|

Implement the repair completion verification procedure again.

• If a malfunction occurs, perform the inspection from Step 1.

|

||

|

5

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Is any other DTC or pending code stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|