FUEL LINE PRESSURE INSPECTION [MZR 1.6]

id0114f4800500

-

Warning

-

• Fuel line spills and leakage from the pressurized fuel system are dangerous. Fuel can ignite and cause serious injury or death and damage. To prevent this, complete the following inspection with the engine stopped.

• Highly pressurized fuel may spray out if the fuel line is cut. Due to the following dangers occurring with a fuel spray, always complete the “Fuel Line Safety Procedure” to prevent the fuel from spraying.

-

― Fuel may cause irritation if it comes in contact with skin and eyes.

― If fuel ignites and causes a fire, it may lead to serious injury or death, and damage to property and facilities.

• A person charged with static electricity could cause a fire or explosion, resulting in death or serious injury. Before performing work on the fuel system, discharge static electricity by touching the vehicle body.

-

Caution

-

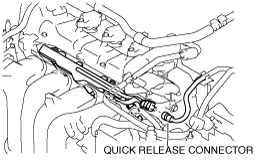

• Disconnecting/connecting the quick release connector without cleaning it may possibly cause damage to the fuel pipe and quick release connector. Always clean the quick release connector joint area before disconnecting/connecting using cloth or soft brush, and make sure that it is free of foreign material.

1. Complete the “BEFORE SERVICE PRECAUTION”. (See BEFORE SERVICE PRECAUTION [MZR 1.6].)

2. Disconnect the negative battery cable. (See NEGATIVE BATTERY CABLE DISCONNECTION/CONNECTION [MZR 1.6].)

3. Disconnect the quick release connector. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [MZR 1.6].)

4. Turn the lever of the SST parallel to the hose as shown in the figure.

5. Insert the SST quick release connector into the fuel pipe until a click is heard.

6. Verify that the quick release connector is firmly connected by pulling it by hand.

7. Start the fuel pump using the following procedure.

-

Using M-MDS

-

2. Connect the M-MDS to the DLC-2.

-

Without using M-MDS

-

1. Remove the fuel pump relay.

-

Caution

-

• Short the specified terminals because shorting the wrong terminal of the relay and fuse block may cause malfunctions.

2. Using a jumper wire, short fuel pump relay terminals C and D in the relay and fuse block.

8. Operate the fuel pump for 10 s.

9. Measure the fuel line pressure.

-

• If not within the specification, inspect the following:

If it less than the specification:

-

― Fuel pump unit

― Fuel line for clogging or leakage

If it exceeds the specification:

-

― Fuel line clogging

-

Fuel pressure

-

335—450 kPa {3.42—4.58 kgf/cm2, 48.6—65.2 psi}

10. Stop the fuel pump using the following procedure.

-

Using M-MDS

-

-

Without using M-MDS

-

1. Disconnect the negative battery cable to stop the fuel pump.

11. Measure the fuel hold pressure after 5 min.

-

• If not within the specification, inspect the following:

-

― Fuel line leakage

-

Fuel hold pressure

-

220 kPa {2.24 kgf/cm2, 31.9 psi} or more

12. Complete the “BEFORE SERVICE PRECAUTION”. (See BEFORE SERVICE PRECAUTION [MZR 1.6].)

13. Disconnect the SST.

14. Connect the quick release connector. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [MZR 1.6].)

15. Complete the “AFTER SERVICE PRECAUTION”. (See AFTER SERVICE PRECAUTION [MZR 1.6].)