CHARCOAL CANISTER INSPECTION [MZR 1.6]

id011607800500

Leakage Inspection

1. Perform the following procedures:

-

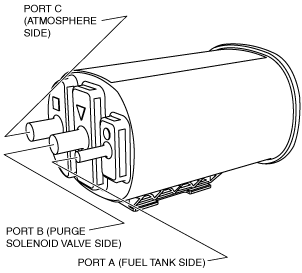

• Assemble the hose used for inspection to port A.

• Cover ports B and C with the caps.

-

Caution

-

• Do not apply a pressure 20 kPa {150 mmHg, 5.91 inHg} or more to the charcoal canister for 1 min. or more. Doing so will damage the charcoal canister.

2. Apply pressure (19.6 kPa {147 mmHg, 5.79 inHg}) through the hose, and verify that air does not leak from the charcoal canister.

-

• If there is no airflow, perform the following “Airflow Inspection”. (See

Airflow Inspection.)

Airflow Inspection

1. Perform the following procedure to verify the charcoal canister airflow.

-

Between port A and port C

-

2. Apply a pressure of 0.98 kPa {7.4 mmHg, 0.29 inHg} to port A.

3. Verify that there is airflow from port C.

-

-

Between port B and port C

-

2. Apply a pressure of 0.98 kPa {7.4 mmHg, 0.29 inHg} to port C.

3. Verify that there is airflow from port B.

-