DTC U2300:00

Global central configuration error

DETECTION CONDITION

• Any of following conditions occurs:

-

― No configuration of the instrument cluster.― The configuration signal with the estimated CAN ID is not sent from the instrument cluster.― The configuration signal value sent via CAN from the instrument cluster is unknown or invalid.― The configuration signal value sent via CAN from the instrument cluster is a value other than the estimated value.― The configuration signal value sent via CAN from the instrument cluster does not match the PCM value.

Diagnostic support note

• This is a continuous monitor (other).

• The check engine light does not illuminate.

• FREEZE FRAME DATA (Mode 2)/Snapshot data is not available.

• DTC is stored in the PCM memory.

FAIL-SAFE FUNCTION

• Operates by the previously learned configuration value.

POSSIBLE CAUSE

• CAN drive error (instrument cluster or PCM)

• Configuration data for the instrument cluster is incorrectly set

• CAN communication line malfunction between instrument cluster and PCM

-

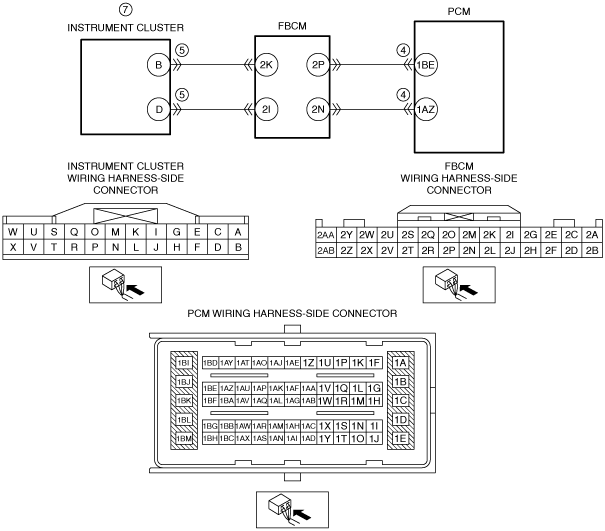

― Instrument cluster terminal B—Front body control module (FBCM) terminal 2K― Instrument cluster terminal D—Front body control module (FBCM) terminal 2I― Front body control module (FBCM) terminal 2P—PCM terminal 1BE― Front body control module (FBCM) terminal 2N—PCM terminal 1AZ

• PCM connector or terminals malfunction

• Instrument cluster connector or terminals malfunction

• Instrument cluster loose

• Instrument cluster malfunction

• Error in non-volatile memory in PCM

• PCM malfunction