FUEL DRAINING PROCEDURE [MZR 1.6]

id0114f4853500

-

Warning

-

• Highly pressurized fuel may spray out if the fuel line is cut. Due to the following dangers occurring with a fuel spray, always complete the “Fuel Line Safety Procedure” to prevent the fuel from spraying.

-

― Fuel may cause irritation if it comes in contact with skin and eyes.

― If fuel ignites and causes a fire, it may lead to serious injury or death, and damage to property and facilities.

• A person charged with static electricity could cause a fire or explosion, resulting in death or serious injury. Before performing work on the fuel system, discharge static electricity by touching the vehicle body.

Fuel Siphoning Procedure Using Fuel Pump

-

Caution

-

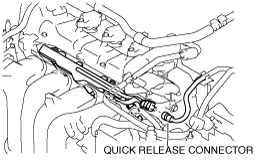

• Disconnecting/connecting the quick release connector without cleaning it may possibly cause damage to the fuel pipe and quick release connector. Always clean the quick release connector joint area before disconnecting/connecting using cloth or soft brush, and make sure that it is free of foreign material.

1. Complete the “BEFORE SERVICE PRECAUTION”. (See BEFORE SERVICE PRECAUTION [MZR 1.6].)

2. Disconnect the quick release connector as shown in the figure. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [MZR 1.6].)

3. Connect a long hose to the disconnected quick release connector and drain the fuel into a container used for collecting gasoline.

4. Drain the fuel from the fuel tank using the following procedure:

-

Caution

-

• The fuel pump could be damaged if it is operated while there is no fuel in the fuel tank. Verify the amount of fuel being discharged from the hose and stop operation of the fuel pump when essentially no fuel is being discharged.

-

Using M-MDS

-

1. Connect the M-MDS to the DLC-2.

-

-

Without using M-MDS

-

2. Remove the fuel pump relay.

-

Caution

-

• Short the specified terminals because shorting the wrong terminal of the relay and fuse block may cause malfunctions.

3. Using a jumper wire, short fuel pump relay terminals C and D in the relay and fuse block.

-

5. Stop the fuel pump using the following procedure.

-

Using M-MDS

-

-

Without using M-MDS

-

1. Remove the jumper wire to stop the fuel pump.

Fuel Siphoning Procedure Not Using Fuel Pump

1. Complete the “BEFORE SERVICE PRECAUTION”. (See BEFORE SERVICE PRECAUTION [MZR 1.6].)

2. Perform the following procedure (1) to (3) if the fuel gauge value is 3/4 or more. If the fuel gauge value is 3/4 or less, go to Step 3.

-

Caution

-

• If an excessive length of hose is inserted into the fuel-filler pipe, the hose will push the non-return valve and the hose may enter the fuel tank. If the hose enters the fuel tank, the hose may get stuck on the non-return valve when the hose is pulled and the non-return valve could be damaged. Do not insert the hose more than the specified length.

• When removing the hose from the fuel-filler opening, use a rag to prevent fuel spatter.

-

Note

-

• Cut the tip of the hose diagonally so that it can be inserted into the fuel-filler pipe smoothly.

• When inserting the hose into the fuel-filler pipe, the hose may get stuck. In such cases, rotate the hose so that the hose can be inserted easily.

• The pump siphons all the fuel that leaked out of the non-return valve and was trapped in the joint hose, then it suctions the air. After siphoning the fuel, wait several seconds until the air is suctioned out, then resume siphoning.

-

1. Cut the tip of the hose diagonally and place a mark at the position of the specified hose insertion length.

Hose insertion length (specified value)

-

1022 mm {40.24 in}

Hose type (reference)

-

Oil-resistant plastic hose of 10 mm {0.4 in} outer diam.×6 mm {0.2 in} inner diam. or equivalent

2. Insert the hose from the fuel-filler opening by rotating it to the marked position.

3. Using a pump, siphon the fuel until the fuel gauge value reaches 3/4 or less.

3. Remove the fuel pump unit. (See FUEL PUMP UNIT REMOVAL/INSTALLATION [MZR 1.6].)

4. Drain the fuel.

5. Remove the hose using a rag.