DTC P242D:00

Exhaust gas temperature sensor No.3 circuit high input

DETECTION CONDITION

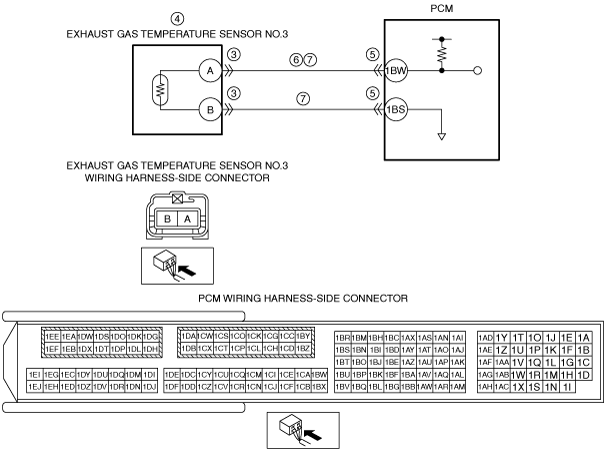

• The PCM monitors the exhaust gas temperature sensor No.3 signal. If the PCM detects that the exhaust gas temperature sensor No.3 voltage at the PCM terminal 1BW is above 4.96 V for 10 s, the PCM determines that the exhaust gas temperature sensor No.3 circuit has a malfunction.

-

― Battery voltage: 8—20 V― Between the elapsed time of 14 to 70 min. after the ignition is switched on (engine on).― Engine speed: above 700 rpm― Engine coolant temperature: above 60 °C {140 °F}― Intake air temperature: −10 °C {14 °F}― Charge air temperature: −10 °C {14 °F}― Vehicle speed: above 25 km/h {16 mph} continues for 10 min or more― Fuel injection amount: 20 mm3/st or more― Total fuel injection amount: 400,000 mm3 or more― The following DTCs are not detected:

-

• IAT sensor No.1: P0112:00, P0113:00• ECT sensor: P0117:00, P0118:00• IAT sensor No.2: P007C:00, P007D:00• VSS: P0500:00

-

MONITORING CONDITIONS

Diagnostic support note

• This is a continuous monitor (CCM).

• The check engine light illuminates if the PCM detects the above malfunction condition during the first drive cycle.

• FREEZE FRAME DATA (Mode 2)/Snapshot data is available.

• DTC is stored in the PCM memory.

FAIL-SAFE FUNCTION

• PCM restricts engine torque.

• Inhibits the EGR control.

• Inhibits the diesel particulate filter regeneration control.

• Inhibits engine-stop by operating the i-stop function.

• PCM restricts engine-transaxle integration control.

POSSIBLE CAUSE

• Exhaust gas temperature sensor No.3 connector or terminals malfunction

• Exhaust gas temperature sensor No.3 malfunction

• PCM connector or terminals malfunction

• Short to power supply in wiring harness between exhaust gas temperature sensor No.3 terminal A and PCM terminal 1BW

• Open circuit in wiring harness between the following terminals:

-

― Exhaust gas temperature sensor No.3 terminal A—PCM terminal 1BW― Exhaust gas temperature sensor No.3 terminal B—PCM terminal 1BS

• PCM malfunction