Description

Cluster switch circuit malfunction

Detection condition

• Instrument cluster detects an open circuit in the cluster switch circuit for 5 s or more with the ignition switched ON (engine off or on).

Fail-safe function

Not applicable

Possible cause

• Cluster switch connector or terminal malfunction

• Instrument cluster connector or terminal malfunction

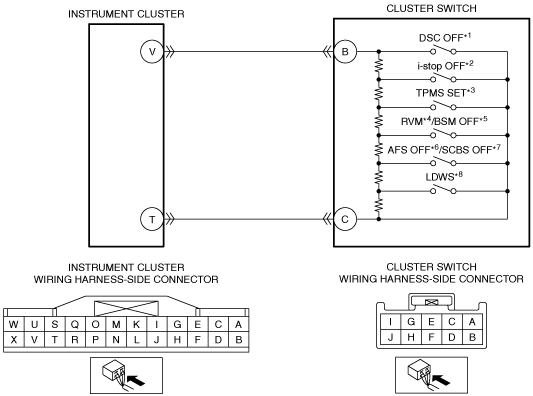

• Open circuit in wiring harness between the following terminals:

-

― Instrument cluster terminal V—Cluster switch terminal B― Instrument cluster terminal T—Cluster switch terminal C

• Cluster switch malfunction

• Instrument cluster malfunction