AUTOMATIC TRANSAXLE REMOVAL/INSTALLATION [FN4A-EL]

id051701294100

-

Caution

-

• Secure the steering wheel using tape or a cable to prevent the steering shaft from rotating after disconnecting the steering shaft. If the steering wheel rotates after the steering shaft and the steering gear and linkage are disconnected, the internal parts of the clock spring could be damaged.

• Secure the steering wheel using tape or a cable to prevent the steering shaft from rotating after disconnecting the steering shaft. If the steering wheel rotates after the steering shaft and the steering gear and linkage are disconnected, the internal parts of the clock spring could be damaged.

Removal

1. Disconnect the negative battery cable. (See NEGATIVE BATTERY CABLE DISCONNECTION/CONNECTION [MZR 1.6].)

2. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

3. Remove the front splash shield. (See SPLASH SHIELD REMOVAL/INSTALLATION.)

4. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FN4A-EL].)

5. Disconnect and/or remove the following parts in the engine compartment.

- (1) Remove the air cleaner and air hose as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZR 1.6].)

-

- (2) Remove the battery tray and PCM component. (See BATTERY REMOVAL/INSTALLATION [MZR 1.6].)

-

- (3) Disconnect the selector cable from the transaxle. (See AUTOMATIC TRANSAXLE SHIFT MECHANISM REMOVAL/INSTALLATION.)

-

- (4) Disconnect the connectors and GND wiring harness from the transaxle.

-

- (5) Remove the selector cable bracket from the transaxle.

-

- (6) Disconnect the oil cooler from the transaxle with the hose connected. (See OIL COOLER REMOVAL/INSTALLATION [FN4A-EL].)

-

- (7) Remove the filler tube from the transaxle.

-

- (8) Remove the starter. (See STARTER REMOVAL/INSTALLATION [MZR 1.6].)

-

6. Disconnect and/or remove the following parts related to the suspension and axle.

- (1) Remove the front tires. (See GENERAL PROCEDURES (FRONT AND REAR AXLES).)

-

- (2) Disconnect the front ABS wheel-speed sensors from the steering knuckles. (See FRONT ABS WHEEL-SPEED SENSOR REMOVAL/INSTALLATION.)

-

- (3) Disconnect the clip securing the brake hose from the shock absorber. (See BRAKE HOSE (FRONT) REMOVAL/INSTALLATION.)

-

- (4) Disconnect the tie-rod end ball joints from the steering knuckles. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [MZR 1.6].)

-

- (5) Disconnect the front lower arms from the steering knuckles. (See FRONT LOWER ARM REMOVAL/INSTALLATION.)

-

- (6) Disconnect the front stabilizer control links from the shock absorbers. (See FRONT SHOCK ABSORBER AND COIL SPRING REMOVAL/INSTALLATION.)

-

- (7) Disconnect the front drive shaft (LH) from the transaxle. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

-

- (8) Disconnect the front drive shaft (RH) from the transaxle. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

-

- (9) Remove the front crossmember component and No.1 engine mount rubber as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [MZR 1.6].)

-

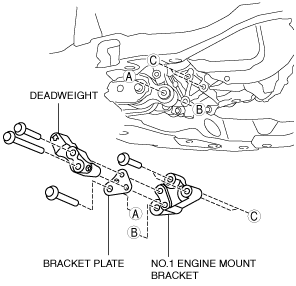

7. Remove the deadweight, bracket plate and No.1 engine mount bracket from the transaxle.

8. Install the SST using the following procedure.

-

Caution

-

• Refer to the SST instruction manual for the basic handing procedure.

- (1) Install one front foot No.2 to each of the left and right front shafts of the SST.

-

- (2) Protect the positions shown in the figure using tape.

-

- (3) To enable to install the SST, disconnect the clip shown in the figure and set the wiring harness aside.

-

- (4) Install the SST using part number 99794 1025 or an M10 × 1.25, length 25 mm {0.98 in} bolt as shown in the figure.

-

Engine front side

-

Tightening torque

-

38—51 N·m {3.9—5.2 kgf·m, 29—37 ft·lbf}

Engine rear side

-

Tightening torque

-

38—51 N·m {3.9—5.2 kgf·m, 29—37 ft·lbf}

- (5) As shown in the figure, set the rear shafts of the SST to the left and right shock absorber nuts.

-

- (6) As shown in the figure, set the front shafts of the SST to the left and right bolts.

-

- (7) When assembling the SST (49 L017 5A0), disconnect the fuel hose from the clip shown in the figure to prevent interference between the fuel hose and SST.

-

- (8) Install the SST (49 L017 5A0) to the SST (49 C017 5A0) as shown in the figure.

-

- (9) Install the SST (49 L017 5A0) to the SST (49 UN30 3050) with the hook of the SST (49 L017 5A0) facing outward.

-

- (10) Adjust the height of the left and right side bars so that they are leveled, then tighten each part of the SST.

-

- (11) Apply tension to the chain to secure the engine.

-

9. Remove in the order indicated in the table.

-

Warning

-

• Improperly jacking a transaxle is dangerous. It can slip off the jack and may cause serious injury.

-

Caution

-

• To prevent the torque converter and transaxle from separating, remove the transaxle without tilting it toward the torque converter.

|

1

|

Torque converter installation nuts

|

|

2

|

Transaxle mounting bolts (upper side)

|

|

3

|

Bracket

|

|

4

|

No.4 engine mount bracket

|

|

5

|

No.4 engine mount support bracket

|

|

6

|

Transaxle mounting bolts (lower side)

|

|

7

|

Transaxle

|

Torque Converter Installation Nuts Removal Note

1. Hold the crankshaft pulley to prevent drive plate from rotating.

2. Remove the torque converter nuts from the starter installation hole.

No.4 engine mount bracket removal note

-

Caution

-

• A slot has been adopted for the No.4 engine mount bracket installation hole. If the No.4 engine mount bracket is deviated from the original position when installing the No.4 engine mount, engine noise or vibration could increase. When removing the No.4 engine mount, place alignment marks on the No.4 engine mount bracket so that they can be assembled to the same positions as before removal.

1. Place alignment marks on the locations shown in the figure so that they can be assembled to the same positions as before removal.

-

Note

-

• Paint so that the outline of the nut is framed on the bracket side.

2. Remove the No.4 engine mount bracket.

Transaxle Mounting Bolts (Lower Side) Removal Note

1. Adjust the SST and lean the engine toward the transaxle.

2. Support the transaxle on a jack.

3. Remove the transaxle mounting bolts (lower side).

4. Remove the transaxle.

Installation

-

Caution

-

• Verify that the torque converter stud bolts are inserted into the drive plate bolt holes, and install the transaxle installation bolts. Otherwise, the drive plate could be damaged.

1. Verify that the torque converter stud bolts are inserted into the drive plate bolt holes from the starter installation hole.

2. Install the transaxle mounting bolts.

|

No.

|

Tightening torque

|

|

A

|

64—89 N·m {6.6—9.0 kgf·m, 48—65 ft·lbf}

|

|

B

|

38—52 N·m {3.9—5.3 kgf·m, 29—38 ft·lbf}

|

3. Tighten the stud bolts for the transaxle.

-

Note

-

• If the No.4 engine mount support bracket nut is loosened, tighten the stud bolts for the transaxle because they may be loosened.

4. Install the No.4 engine mount bracket to No.4 engine mount rubber, and temporarily tighten the installation bolt.

5. Tighten the No.4 engine mount support bracket installation bolts in the order shown in the figure.

-

Tightening torque

-

61—76 N·m {6.3—7.7 kgf·m, 45—56 ft·lbf}

6. Tighten the No.4 engine mount support bracket stud bolts.

-

Note

-

• If the No.4 engine mount bracket nut is loosened, tighten the stud bolts for the transaxle because they may be loosened.

7. Pull up the transaxle using the SSTs, pass the No.4 engine mount support bracket stud bolts through the No.4 engine mount bracket, and temporarily tighten the No.4 engine mount installation nuts.

8. Install the No.1 engine mount bracket, the bracket plate and deadweight to the transaxle, and temporarily tighten the installation bolts.

9. Install the front crossmember component and No.1 engine mount rubber as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [MZR 1.6].)

10. Temporarily tighten the No.1 engine mount rubber installation bolts.

11. Align the alignment marks on the No.4 engine mount bracket and nuts, and temporarily tighten the nuts shown in the figure.

12. Tighten the No.4 engine mount bracket installation nuts and bolt in the order shown in the figure.

|

No.

|

Tightening torque

|

|

1, 2, 3

|

92—116 N·m {9.4—11 kgf·m, 69—85 ft·lbf}

|

|

4

|

81—99 N·m {8.3—10 kgf·m, 60—73 ft·lbf}

|

13. Tighten the No.1 engine mount bracket and bracket plate installation bolts in the order shown in the figure.

-

Tightening torque

-

59—68 N·m {6.1—6.9 kgf·m, 44—50 ft·lbf}

14. Remove the SSTs (49 C017 5A0, 49 L017 5A0).

15. Tighten the No.1 engine mount rubber installation bolts.

16. Fix the crankshaft pulley to lock the torque converter against rotation.

-

Caution

-

• After temporarily tightening the torque converter installation nut uniformly, tighten it to the specified torque.

17. Tighten the torque converter installation nuts.

-

Tightening torque

-

41—54 N·m {4.2—5.5 kgf·m, 31—39 ft·lbf}

18. Connect and/or install the following parts related to the suspension and axle.

- (1) Connect the front drive shaft (RH) to the transaxle. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

-

- (2) Connect the front drive shaft (LH) to the transaxle. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

-

- (3) Connect the front stabilizer control links to the shock absorbers. (See FRONT SHOCK ABSORBER AND COIL SPRING REMOVAL/INSTALLATION.)

-

- (4) Connect the front lower arms to the steering knuckles. (See FRONT LOWER ARM REMOVAL/INSTALLATION.)

-

- (5) Connect the tie-rod end ball joints to the steering knuckles. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION [MZR 1.6].)

-

- (6) Connect the clip securing the brake hose to the shock absorber. (See BRAKE HOSE (FRONT) REMOVAL/INSTALLATION.)

-

- (7) Connect the front ABS wheel-speed sensors to the steering knuckles. (See FRONT ABS WHEEL-SPEED SENSOR REMOVAL/INSTALLATION.)

-

- (8) Install the front tires. (See GENERAL PROCEDURES (FRONT AND REAR AXLES).)

-

19. Connect and/or install the following parts in the engine compartment.

- (1) Install the starter. (See STARTER REMOVAL/INSTALLATION [MZR 1.6].)

-

- (2) Install the filler tube from the transaxle.

-

- (3) Connect the oil cooler to the transaxle with the hose connected. (See OIL COOLER REMOVAL/INSTALLATION [FN4A-EL].)

-

- (4) Install the selector cable bracket to the transaxle. (See AUTOMATIC TRANSAXLE SHIFT MECHANISM REMOVAL/INSTALLATION.)

-

- (5) Connect the connectors and GND wiring harness to the transaxle.

-

- (6) Connect the selector cable to the transaxle.

-

- (7) Install the battery tray and PCM component. (See BATTERY REMOVAL/INSTALLATION [MZR 1.6].)

-

- (8) Install the air cleaner and air hose as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [MZR 1.6].)

-

20. Connect the negative battery cable. (See NEGATIVE BATTERY CABLE DISCONNECTION/CONNECTION [MZR 1.6].)

21. Add ATF to the specified level. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [FN4A-EL].)

22. Perform the following test according to the service item. (See MECHANICAL SYSTEM TEST [FN4A-EL].)(See ROAD TEST [FN4A-EL].)

|

Service item

|

Test item

|

|

Line pressure test

|

Stall test

|

Time lag test

|

Road test

|

|

ATX replacement

|

×

|

|

|

|

|

ATX overhaul

|

×

|

×

|

×

|

×

|

|

Torque converter replacement

|

×

|

×

|

|

|

|

Oil pump replacement

|

×

|

|

|

|

|

Clutch system replacement

|

×

|

|

×

|

×

|

× :Test to be performed after the service work

23. Install the front splash shield. (See SPLASH SHIELD REMOVAL/INSTALLATION.)

24. Install the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)