|

1

|

VERIFY TCM DTCs

• Retrieve the TCM DTCs using the M-MDS.

• Are any DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY PCM DTCs

• Retrieve the PCM DTCs using the M-MDS.

• Are any DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT TCM CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery cable.

• Disconnect the TCM connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 9.

|

|

4

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 9.

|

|

5

|

INSPECT START STOP UNIT CONNECTOR CONDITION

• Disconnect the start stop unit connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 9.

|

|

6

|

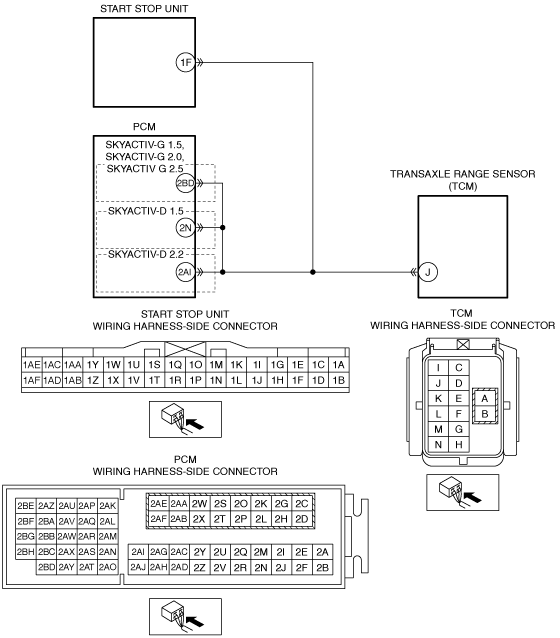

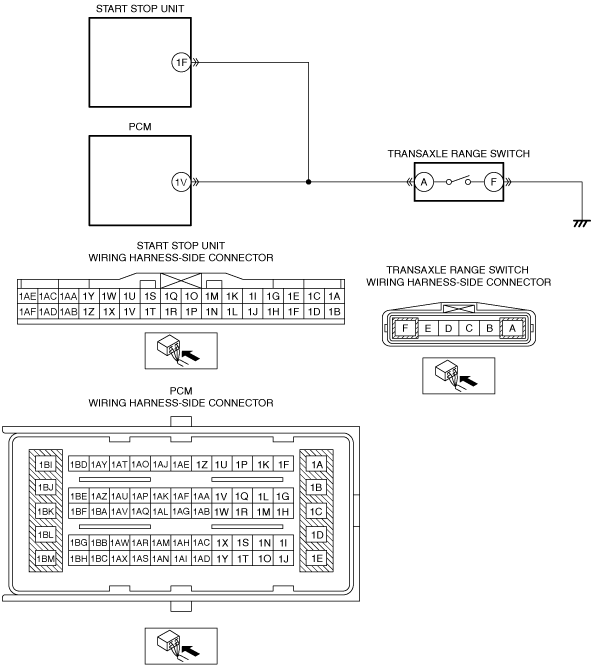

INSPECT FOR SHORT TO POWER SUPPLY IN TRANSAXLE RANGE SENSOR CIRCUIT

• Always reconnect all disconnected connectors.

• Reconnect the negative battery cable.

• Operate the selector lever to P or N position.

• Measure the voltage at the start stop unit terminal 1F (wiring harness-side).

• Is the voltage 1.0 V or less?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• TCM terminal J—PCM terminal 2BD (SKYACTIV-G 1.5, SKYACTIV-G 2.0, SKYACTIV-G 2.5)

• TCM terminal J—PCM terminal 2N (SKYACTIV-D 1.5)

• TCM terminal J—PCM terminal 2AI (SKYACTIV-D 2.2)

• TCM terminal J—Start stop unit terminal 1F

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

Go to Step 9.

|

|

7

|

PERFORM DTC INSPECTION AND VERIFY TRANSAXLE RANGE SENSOR MALFUNCTION

• Always reconnect all disconnected connectors.

• Reconnect the negative battery cable.

• Clear the DTC for the start stop unit using the M-MDS.

• Switch the ignition ON (engine off).

• Perform the following work 5 times or more.

-

― Operate the selector lever to P or N position and wait for 1 s or more.

― Operate the selector lever to other than P and N position and wait for 1 s or more.

― Operate the selector lever to P or N position.

• Retrieve the start stop unit DTCs using the M-MDS.

• Is the same DTC displayed?

|

Yes

|

Replace the TCM, then go to the next step.

|

|

No

|

Go to Step 10.

|

|

8

|

PERFORM DTC INSPECTION AND VERIFY PCM MALFUNCTION

• Clear the DTC for the start stop unit using the M-MDS.

• Switch the ignition ON (engine off).

• Perform the following work 5 times or more.

-

― Operate the selector lever to P or N position and wait for 1 s or more.

― Operate the selector lever to other than P and N position and wait for 1 s or more.

― Operate the selector lever to P or N position.

• Retrieve the start stop unit DTCs using the M-MDS.

• Is the same DTC displayed?

|

Yes

|

Replace the PCM, then go to the next step.

|

|

No

|

Go to Step 10.

|

|

9

|

VERIFY THAT REPAIRS HAVE BEEN COMPLETED

• Always reconnect all disconnected connectors.

• Reconnect the negative battery cable.

• Clear the DTC for the start stop unit using the M-MDS.

• Switch the ignition ON (engine off).

• Perform the following work 5 times or more.

-

― Operate the selector lever to P or N position and wait for 1 s or more.

― Operate the selector lever to other than P and N position and wait for 1 s or more.

― Operate the selector lever to P or N position.

• Retrieve the start stop unit DTCs using the M-MDS.

• Is the same DTC displayed?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the start stop unit.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

10

|

VERIFY IF OTHER DTCs DISPLAYED

• Are any other DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|