STEP

INSPECTION

ACTION

1

RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the FREEZE FRAME DATA/snapshot data on the repair order.

—

Go to the next step.

2

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

Yes

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

VERIFY RELATED PENDING CODE AND/OR DTC

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Are any other PENDING CODEs and/or DTCs present?

Yes

If DTC P1142:00, P2104:00 or P2263:00 is stored:

• Go to the next step.

If DTC other than P1142:00, P2104:00 or P2263:00 is stored:

• Go to the applicable PENDING CODE or DTC inspection.

(See DTC TABLE [SKYACTIV-D 1.5].)

No

Go to the next step.

4

DETERMINE IF MALFUNCTION IS CAUSED BY TURBOCHARGER WITH VARIABLE TURBINE GEOMETRY

• Switch the ignition off.

• Switch the ignition ON (engine on).

• Display PID VGTURB_ACT and simulation item VGTURB_DSD using the M-MDS.

• Operate the turbocharger with variable geometry using simulation item VGTURB_DSD.

• Does PID VGTURB_ACT change according to the simulation operation?

Yes

Go to Step 18.

No

Go to the next step.

5

INSPECT VACUUM CHAMBER

• Inspect the vacuum chamber.

• Is there any malfunction?

Yes

Replace the cylinder head cover, then go to Step 9.

No

Go to the next step.

6

INSPECT VACUUM PIPING

• Inspect vacuum piping at the following:

-

― Power brake unit—Vacuum pump― Vacuum pump—Check valve― Check valve—Vacuum chamber― Vacuum chamber—Turbocharger solenoid valve― Turbocharger solenoid valve—Turbocharger actuator

• Is there hose leakage or damage in the vacuum piping?

Yes

Repair or replace the malfunctioning part according to the inspection results, then go to Step 9.

No

Go to the next step.

7

INSPECT TURBOCHARGER SOLENOID VALVE

• Inspect the turbocharger solenoid valve.

• Is there any malfunction?

Yes

Replace the turbocharger solenoid valve, then go to Step 9.

No

Go to the next step.

8

INSPECT CHECK VALVE

• Inspect the check valve.

• Is there any malfunction?

Yes

Replace the check valve, then go to the next step.

No

Replace the turbocharger with variable turbine geometry, then go to Step 18.

9

DETERMINE IF MALFUNCTION IS CAUSED BY TURBOCHARGER WITH VARIABLE TURBINE GEOMETRY

• Switch the ignition off.

• Switch the ignition ON (engine on).

• Display PID VGTURB_ACT and simulation item VGTURB_DSD using the M-MDS.

• Operate the turbocharger with variable geometry using simulation item VGTURB_DSD.

• Does PID VGTURB_ACT change according to the simulation operation?

Yes

Go to the next step.

No

Replace the turbocharger with variable turbine geometry, then go to Step 18.

10

VERIFY IF METAL FRAGMENTS PENETRATED ENGINE OIL

• Drain the engine oil.

• Are there metal fragments in the drained engine oil?

Yes

Replace or overhaul the engine as a partial engine unit.

Refer to the Mazda Workshop Manual.

Go to Step 18.

No

Go to the next step.

11

REMOVE ANY ENGINE OIL IN THE PISTON CAVITY.

• Remove the glow plug.

• Hold cloth over the glow plug installation hole.

• Crank the engine and remove the engine oil from the glow plug installation hole.

—

Go to the next step.

12

INSPECT ENGINE COMPRESSION

• Inspect the engine compression.

• Are compression pressures within specification?

Yes

Go to the next step.

No

Repair or replace the malfunctioning part according to the inspection results, then go to Step 18.

13

INSPECT WATER-COOLED CHARGE AIR COOLER CORE CONDITION

• Visually inspect the water-cooled charge air cooler core condition.

• Is there any engine oil in the core of the water-cooled charge air cooler?

Yes

Blow the core of the water-cooled charge air cooler with compressed air to remove the engine oil.

Clean or replace the water-cooled charge air cooler, then go to the next step.

No

Inspect restrict in water-cooled charge air cooler coolant passage.

• If malfunction is detected:

-

― Repair or replace the malfunctioning part, then go to the next step.

• If normal:

-

― Go to the next step.

14

VERIFY CONDITION OF BOTTOM SURFACE IN INTAKE MANIFOLD

• Verify condition of bottom surface in intake manifold.

• Is there any engine oil on the bottom in the intake manifold?

Yes

Remove any engine oil on the bottom in the intake manifold, then go to the next step.

No

Go to the next step.

15

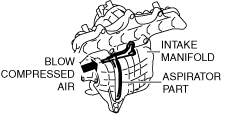

INSPECT INTAKE MANIFOLD ASPIRATOR PART FOR FOREIGN MATTER

• Blow compressed air into the intake manifold aspirator part (inside the passage) from the direction of the arrow shown in the figure and remove any foreign matter.

•

am3zzw00020268

|

—

Go to the next step.

16

INSPECT MAP SENSOR

• Reconnect all disconnected connectors.

• Inspect the MAP sensor.

• Is there any malfunction?

Yes

Replace the MAP sensor/boost air temperature sensor, then go to the next step.

No

Go to the next step.

17

INSPECT EXHAUST GAS PRESSURE SENSOR NO.1

• Reconnect all disconnected connectors.

• Inspect the exhaust gas pressure sensor No.1.

• Is there any malfunction?

Yes

Replace the exhaust gas pressure sensor No.1, then go to the next step.

No

Go to the next step.

18

PERFORM COMPULSORY DPF REGENERATION AND BURN OUT ENGINE OIL IN DPF

• Perform the "COMPULSORY DIESEL PARTICULATE FILTER REGENERATION".

-

Note

-

• When a DTC is stored, compulsory DPF regeneration may be performed by the PCM control.

-

― For DTCs P242F:00, the "COMPULSORY DIESEL PARTICULATE FILTER REGENERATION" will only be blocked if an excessive amount of soot is in the diesel particulate filter.

• Compulsory DPF regeneration is performed after performing the applicable DTC troubleshooting.(See DTC TABLE [SKYACTIV-D 1.5].) -

—

Go to the next step.

19

INSPECT ENGINE OIL LEVEL

• Inspect the engine oil level.

• Is the engine oil amount above X line on the dipstick?

Yes

Replace the engine oil.

Perform the “ENGINE OIL DATA RESET”.

Go to the next step.

No

Go to the next step.

20

VERIFY DTC TROUBLESHOOTING COMPLETED

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Perform the “FUEL INJECTOR INJECTION AMOUNT CORRECTION”.

• Start the engine and warm it up completely.

-

Caution

-

• While performing this step, always operate the vehicle in a safe and lawful manner.• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

• Drive the vehicle under the FREEZE FRAME DATA/snapshot data condition.

• Perform the DTC Reading Procedure.

• Is the same DTC present?

Yes

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

No

Go to the next step.

21

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

Yes

Go to the applicable DTC inspection.

(See DTC TABLE [SKYACTIV-D 1.5].)

No

Referring to each adjustment procedure, perform fuel injector injection amount correction and then the diesel particulate filter data reset.

DTC troubleshooting completed.